Overview:

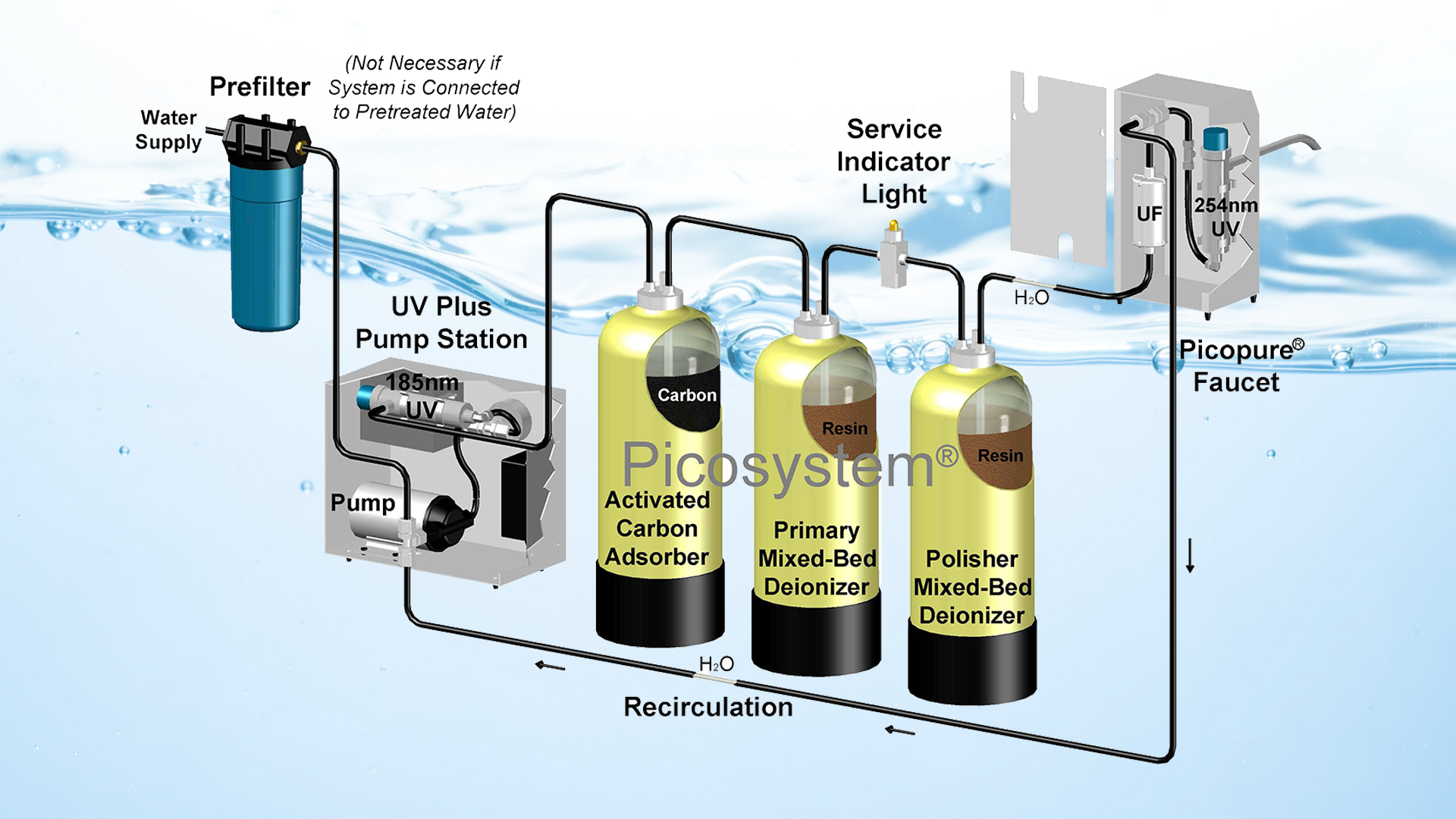

To comprehend how a Picosystem® operates, it is essential to first explore the contaminants it addresses. Hydro groups contaminants into six broad categories: dissolved solids, organics, particulates, microorganisms, microorganism by-products, and dissolved gases. The Picosystem®, exemplified by the 11218 model, comprises a prefilter housing with a 0.2-micron filter cartridge, an activated carbon canister, and two mixed-bed deionizers. The purpose of each treatment within this system is to purify water by targeting specific contaminants.

Prefilter:

The prefilter plays a pivotal role in the efficiency of the Picosystem®. Generally, the quality of the prefilter directly influences the output quality of the Picosystem®. However, it’s crucial to note that a prefilter itself can be a source of contamination. Some membrane prefilters contain a wetting agent (surfactant) that coats the surface. This agent needs to be rinsed off through filter flushing to prevent interference with certain applications. Fortunately, Polyethersulfone filters that Hydro uses, are naturally hydrophilic and do not require a wetting agent.

Activated Carbon:

Granular activated carbon is employed in the Picosystem® to eliminate chlorine, chloramines, and dissolved organics. While creating a chlorine-free environment, it fosters a nutrient-rich space for microorganism growth. Regular replacement of carbon tanks every six months is recommended to prevent the accumulation of microorganisms and by-products that could compromise the system. Carbon fines, generated during shipping, can also pose a problem if not properly flushed out before installation, leading to contamination of the final product.

Mixed-Bed Resins:

New resin contains organics from the manufacturing process. If not removed by several regeneration and exhaustion cycles, which expand and contract the beads (like squeezing a sponge), they can contaminate the product water.

Now, how does a Picosystem® work?

Deionization is a process involving the removal of dissolved mineral salts. The dissolved salts are preferentially exchanged for other ions that are already on the resin bead. The ions that are already on the resin beads (from our regeneration) are: Hydrogen (H+) on cation beads and hydroxyl (OH-) on the anion beads. So, mixed-bed resin, with Type I anion resin, is capable of removing all ionized species and producing 18+ Megohm H2O.

Conclusion:

Tap water contains all sorts of particles, organics, microorganisms, dissolved salts, gasses, etc. The prefilter removes particulates, activated carbon treats chlorine/chloramines and dissolved organics, deionizers remove dissolved solids (salts) and carbon dioxide. Each treatment step is fairly specific in what it removes and one cannot compensate for another’s failure.